Hotline:

133-3102-1811

Chinese

News

首页 > News > Industry information >

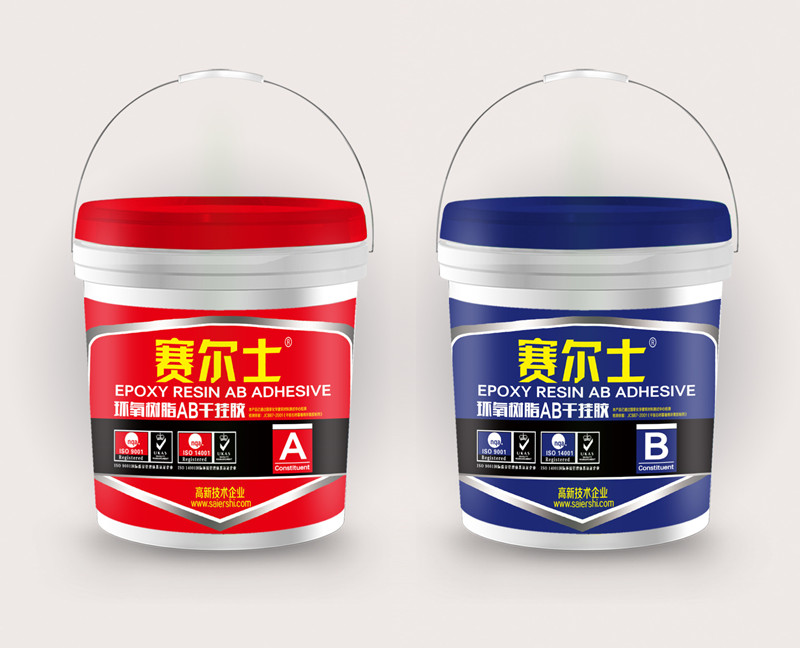

Precautions for preservation and use of stone dry hanging glue

Date:2021-01-03 09:40:00

Share:

1. Storage method:

Store in a dry and ventilated place (above 10 ℃) and seal immediately after use. Components a and B shall not be contacted. The original sealed product can be stored for two years, and the validity period of unsealed product is 12 months.

2. Operating conditions:

1) It is necessary to ensure that the contact area of each square meter of stone slab is not less than 100 square centimeters, and the thickness of glue is not less than 3 mm. The paste surface should be dry and not wet (moisture content should not be higher than 15%), dust-free, oil-free, firm and not loose. When the bonding surface is too smooth, it must be rough, and the substances (dust, dirt, moisture, paint on metal surface, floating rust layer, etc.) that affect the bonding effect on the bonding surface must be removed.

2) At the initial stage of curing, dry hanging adhesive can not bear load

3) When the temperature is below 10 ℃ in winter, all quick drying adhesives should be used. At this time, the effective construction time can be extended to 5-6 minutes; when the construction temperature is lower than 5 ℃, the adhesive part can be heated, but not higher than 65 ℃. During welding and installation in construction, the solder joint should be more than 3cm away from the glue. When the stone material is loose or has many cracks, a layer of strong stone repair glue should be applied on the back of the stone to enhance the rigidity and waterproof performance.

3. Construction precautions:

1) During the construction, please mix a and B glue evenly according to the proportion, and adjust them to the same color until there is no color bar, so as to avoid the imbalance of proportion or uneven mixing, resulting in incomplete curing, and may lead to oil spitting, yellowing, pollution and insufficient adhesiveness.

2) Avoid mixing AB glue directly on the dry hanging board, mix it evenly on the special substrate, and then apply glue at the required position to prevent polluting the board.

3) After curing, AB glue has waterproof and moisture-proof functions, but the glue itself does not have the above functions. Therefore, during construction, AB glue and stone should be avoided to encounter water, otherwise the glue will absorb water, resulting in incomplete curing, sticky surface and insufficient curing strength.

4) At room temperature (25 ℃), the application period of AB adhesive is generally about 30 minutes, the initial drying time is generally about 2 hours, and the complete curing time is generally 24 ~ 72 hours. Generally, the curing speed of AB dry hanging adhesive is slow at low temperature (below 10 ℃), and the cost is higher if the curing speed is to be increased. After curing, the durability of AB dry hanging adhesive is much better than that of dolomite adhesive, but its cost is higher than that of dolomite adhesive.

5) Please ensure that the sizing part is dry, clean and free of ash, otherwise it will lead to the separation of colloid and substrate after curing, resulting in insufficient bond strength.

6) AB glue should be mixed with a glue and B glue in the same batch. If different batches of a and B glue are used, please make sample confirmation before use, and use after passing.

Copyright © 蚌埠赛尔时代工贸有限公司 皖ICP备17024280号

技术支持:智导互联